Benchmark precision

When it comes to quality, we are very exacting. We perform our work with micrometre precision, with quality controls right down to the smallest details.

Our aspiration: zero error. Zero tolerance.

Your advantage: objectivity! Not only we evaluate our services regularly, our customers do so as well. Our quality, reliability and punctuality. The outcome? Always excellent!

Components of our quality assurance system

Worker self-inspection

Every employee checks every individual part directly on the machine, even in series production. Every worker rejects faulty parts directly at STC. This prevents these parts from ever reaching our customers.- In-process quality controls pursuant to EN DIN ISO 9001:2015

2 out of 40 employees take care of 100% of our quality management. They examine all production steps on the machines and the self-inspection carried out by our skilled workers. They lay down the quality assurance measures for new machines and train our staff. We analyse and correct any possible deviations using the 8D method. - Certified first sample testing

We conduct first sample tests pursuant to VDA (dimensional inspection) or QS9000 (PPAP/production part approval process) standards. - Incoming goods and final inspections

No raw material, no part from suppliers is processed before it is approved by our quality management team. Likewise no part, no component, no assembly leaves our facility without receiving final approval. This takes place after final inspection by quality management. - Bench testing

Before each shipment we test our hydraulic pumps and assemblies for our customers in terms of operation and tightness. We draw up our own test report for every unit. - Measuring room

We carry out regular in-process random checks of series components in our climate-controlled measuring room. We inspect all lapped components at 100% via laser measurement. The measuring results are consistently documented. External annual inspections and calibrations of all measuring instruments and measuring machines ensure absolute accuracy.

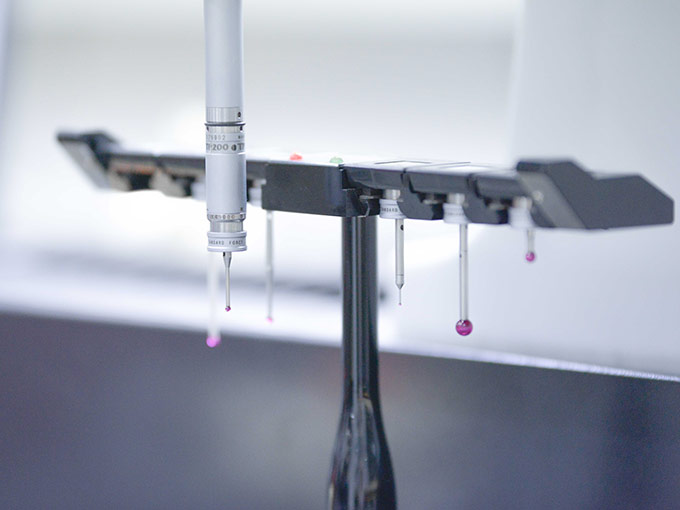

3D coordinate measuring machine

- Manufacturer: Mitutoyo

- Machine: Crystal plus 574

- Measuring range: 500 x 400 x 500 mm

- Accuracy: 0,003 mm

Contour analysis/contour measurement

- Manufacturer: Mahr

- Machine: MarSurf XC10

- Measuring range: 120 mm

- Accuracy: 0,001 mm

Surface Form Analysis System

- Corning

- Machine: Tropel FlatMaster

- Measuring range: 25 mm

- Accuracy: 0,00004 mm